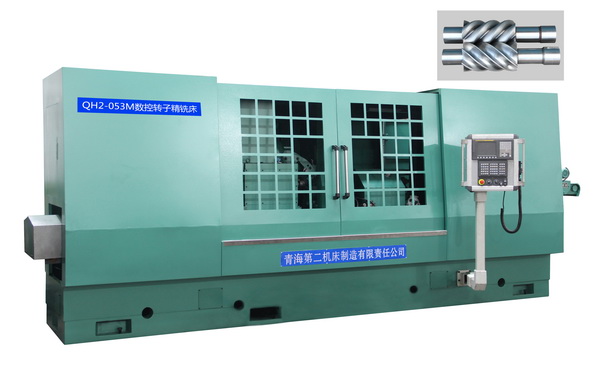

(一)機床的名稱、型號、規格:

機床名稱:高速數控螺旋轉子精銑床 機床型號:QH2-053M

機(ji)床規格(ge):Φ280mm×1300mm(最大(da)加(jia)工(gong)直徑×最大(da)加(jia)工(gong)長(chang)度)

(二)機床主要用途:

QH2-053M數(shu)控螺(luo)(luo)旋(xuan)轉子(zi)(zi)銑床采(cai)用(yong)成型銑刀盤(pan)專門銑削加工(gong)螺(luo)(luo)桿(gan)轉子(zi)(zi)、螺(luo)(luo)桿(gan)等螺(luo)(luo)旋(xuan)面工(gong)件的高(gao)效率專用(yong)精密機床,主(zhu)要適用(yong)于空壓機、冷凍機、工(gong)業(ye)泵等行業(ye)中、小(xiao)規格螺(luo)(luo)旋(xuan)轉子(zi)(zi)的精銑削加工(gong)。

機床采(cai)用倒T字形臥式水平整體布(bu)局。工(gong)件(jian)(jian)在(zai)前(qian),刀具在(zai)后。工(gong)件(jian)(jian)作旋轉(C軸)和縱向(xiang)運動(dong)(Z軸)形成(cheng)螺紋運動(dong)鏈, 銑刀作旋轉切削和橫向(xiang)進(jin)給運動(dong)(X軸)。合成(cheng)后形成(cheng)工(gong)件(jian)(jian)的螺紋面。

機(ji)(ji)床(chuang)數(shu)控(kong)軸(zhou)(zhou)(zhou)數(shu)為三(san)軸(zhou)(zhou)(zhou)/三(san)聯動(dong)(dong)(dong)。分(fen)別完(wan)(wan)成(cheng)(cheng)對機(ji)(ji)床(chuang)如下執行及功能部件(jian)(jian)(jian)的控(kong)制: C軸(zhou)(zhou)(zhou)—工(gong)(gong)件(jian)(jian)(jian)頭(tou)架旋(xuan)轉(zhuan)主(zhu)軸(zhou)(zhou)(zhou)及工(gong)(gong)件(jian)(jian)(jian)槽(cao)數(shu)自動(dong)(dong)(dong)分(fen)度(du)軸(zhou)(zhou)(zhou);X軸(zhou)(zhou)(zhou)—銑(xian)頭(tou)箱(xiang)徑向(xiang)移動(dong)(dong)(dong)/進給(gei)軸(zhou)(zhou)(zhou);Z軸(zhou)(zhou)(zhou)—工(gong)(gong)件(jian)(jian)(jian)工(gong)(gong)作(zuo)臺軸(zhou)(zhou)(zhou)向(xiang)移動(dong)(dong)(dong)/進給(gei)軸(zhou)(zhou)(zhou);其中C軸(zhou)(zhou)(zhou)/Z軸(zhou)(zhou)(zhou)為螺(luo)紋(wen)成(cheng)(cheng)型數(shu)控(kong)聯動(dong)(dong)(dong)軸(zhou)(zhou)(zhou),螺(luo)旋(xuan)轉(zhuan)子(zi)槽(cao)螺(luo)紋(wen)導程運(yun)動(dong)(dong)(dong)由C軸(zhou)(zhou)(zhou)—工(gong)(gong)件(jian)(jian)(jian)頭(tou)架旋(xuan)轉(zhuan)主(zhu)軸(zhou)(zhou)(zhou)和Z軸(zhou)(zhou)(zhou)—工(gong)(gong)作(zuo)臺軸(zhou)(zhou)(zhou)向(xiang)移動(dong)(dong)(dong)/進給(gei)實現(xian)(xian)聯動(dong)(dong)(dong)完(wan)(wan)成(cheng)(cheng)。螺(luo)旋(xuan)轉(zhuan)子(zi)槽(cao)螺(luo)紋(wen)深度(du)由X軸(zhou)(zhou)(zhou)—銑(xian)頭(tou)箱(xiang)徑向(xiang)移動(dong)(dong)(dong)/進給(gei)完(wan)(wan)成(cheng)(cheng)。機(ji)(ji)床(chuang)各軸(zhou)(zhou)(zhou)裝(zhuang)有末端(duan)檢(jian)測裝(zhuang)置,螺(luo)紋(wen)運(yun)動(dong)(dong)(dong)閉環控(kong)制。機(ji)(ji)床(chuang)采(cai)用(yong)FANUC公(gong)司0i-MD數(shu)控(kong)系統(tong)控(kong)制及交流伺服(fu)電(dian)機(ji)(ji)驅(qu)動(dong)(dong)(dong),銑(xian)刀主(zhu)軸(zhou)(zhou)(zhou)采(cai)用(yong)主(zhu)軸(zhou)(zhou)(zhou)電(dian)機(ji)(ji)驅(qu)動(dong)(dong)(dong),可實現(xian)(xian)銑(xian)刀的無級變速。采(cai)用(yong)免(mian)編程參數(shu)化操作(zuo)界面,操作(zuo)簡潔(jie)安全方便。

(三)主要規格參數:

1.最小/最大加工直徑: 最小Φ60mm/最大Φ280mm

2.最小(xiao)/最大安裝長度(du): 最小(xiao)300mm/最大1300mm

3.加工工件導程范圍: 任意

4.加(jia)工(gong)工(gong)件頭(tou)數: 任意

5.最(zui)(zui)小(xiao)/最(zui)(zui)大銑(xian)刀安裝直徑: 最(zui)(zui)小(xiao)127mm/最(zui)(zui)大290mm

6.銑刀最(zui)大(da)安(an)裝寬度: 150mm

7.最(zui)大(da)工件安裝(zhuang)重(zhong)量(liang): 300kg

8.銑刀盤轉(zhuan)速(su)范圍(wei)(無級): 80~400r/min

9.銑刀(dao)主軸傾斜角最大調度范(fan)圍(wei)(從(cong)垂直方向計(ji)) ±60º

10.刀具主軸頭旋轉速度: 0~2min-1

11.工件轉速: 0 min-1~30 min-1

12.主軸頭旋轉夾緊方式(shi): 夾緊(蝶(die)形彈簧)/松口(液壓(ya))

13.刀桿支撐: 滾動軸(zhou)承(軸(zhou)端錐形)手(shou)動拆(chai)裝

14.裝(zhuang)刀軸(zhou): 主(zhu)軸(zhou)一體式

15.銑刀刀桿直徑: 60mm、

16.刀具(ju)主軸頭(tou)的前后運(yun)動(dong)(X軸):

16.1刀具主(zhu)軸頭(tou)前后移動量: 200 mm

16.2主軸頭前(qian)后快(kuai)移(yi)進(jin)給: 10m/min

16.3刀具主(zhu)軸頭和工件主(zhu)軸的軸心距離: 最小120mm/最大(da)320mm

17.銑頭進給速度(du)(X向) : 0~250mm/min

18.銑頭快移速度(X向) : 10m/min

19.銑(xian)刀電(dian)機功(gong)率: 26kw

轉(zhuan)速: 1500r/min

20. 工(gong)作臺左右運動(Z軸):

20.1工作臺左右移動量: 1200 mm

20.2工作臺進給速度(z向(xiang)) : 0~250mm/min

20.3工作臺快移速度(z向) : 10m/min

21.尾(wei)座(zuo)油(you)缸最大行程 60mm-80mm

22. 伺服驅(qu)動軸:

22.1.Z軸交流伺(si)服電機 W=4kw M=22N.m N=3000r/min

22.2.X軸(zhou)交流伺服電機 W=4kw M=22N.m N=3000r/min

22.3. C軸交流伺(si)服(fu)電(dian)機 W=4kw M=22N.m N=3000r/min

23.數控(kong)系統控(kong)制軸(zhou)數 3軸(zhou)(X軸(zhou)、Z軸(zhou)、C軸(zhou))

24.全閉環光刪反饋 3軸(zhou)(X軸(zhou)、Z軸(zhou)、、C軸(zhou))

25.數控系統編(bian)程(cheng)最小單(dan)位 0.001mm

26.機床外形(xing)尺寸(長×寬×高) (4800×2400×2200)mm

37.機床凈重 約13000kg